Wisconsin Custom Tool and Die Manufacturer

High Precision Tool & Die Services in Milwaukee, WI

As a distinguished provider of high-precision tool and die manufacturing services, Mahuta Tool delivers excellence across the board. We have an ISO -9001:2015 certified quality management system. In the ever-evolving precision tool and die industry, our expertise in machine tooling, CMM measuring, gauge making, metal stamping, and efficient die manufacturing sets us apart.

Our Tool & Die Capabilities

Our capabilities as a tool & die shop extend far beyond the creation of tool and die parts, and include 2-D and 3-D CAD modeling, design, prototyping, inspection, engineering, reverse engineering, technical support, and tool history documentation. We also manufacture tooling for checking, welding, and assembly fixtures, as well as inspection gauges and automation equipment.

Our tool and die products are commonly used in the manufacture of drawn shells, perforated shapes, pans and channels, as well as for embossing and engraving. We can produce dies of up to 20,000 lbs. in a wide range of metals, including aluminum, bronze alloys, copper, alloy steel and titanium.

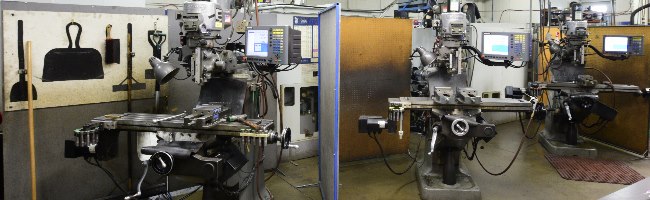

- Machine Tooling: Mahuta Tool uses an array of lathes, grinders, and millers for shaping/machining metal components for a wide range of tools and machinery.

- Die Manufacturing: Our die manufacturing capabilities include coining dies, trim dies, forming dies, draw dies, blanking dies, secondary dies, hand transfer dies, and swaging dies. We offer single hit, progressive and transfer stamping.

- CMM Measuring: We use our coordinate measuring machine (CMM) to get precise measurements of pieces we are reverse engineering, as well as to ensure prototypes and finished pieces are accurate.

- Jig & Fixture: Our tooling capabilities include checking fixtures, welding fixtures, inspection gauges/fixtures, assembly fixtures, and automation equipment.

- Gauge Making: Mahuta Tool prototypes and manufacturers precision gauges for use in a wide range of applications.

- Metal Stamping: We can handle a wide range of metal stamping work.

Our Tool & Die Services - Wisconsin Based Tool & Die Shop

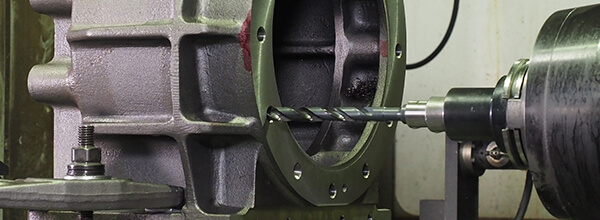

Machine Tooling

As a prominent machine tooling manufacturer, we utilize a range of lathes, grinders, and millers for shaping/machining metal components across various tools and machinery. Combining years of experience with the latest technology, we ensure unmatched quality results for every project.

Learn more about our machine tooling services.

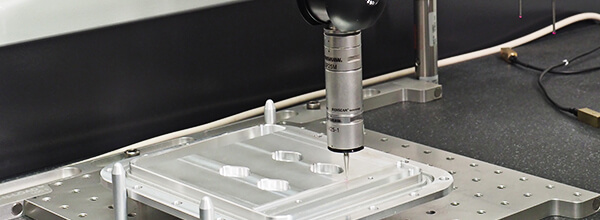

CMM Measuring

Our cost-effective CMM measuring services in Milwaukee employ advanced Coordinate Measuring Machine (CMM) technology to ensure extremely precise measurements of components, including those we are reverse engineering, assuring the accuracy of prototypes and finished pieces to the highest industry standards.

Learn more about our CMM measuring services.

Jig and Fixture

Our comprehensive services include creating checking fixtures, welding fixtures, inspection gauges/fixtures, assembly fixtures, and automation equipment - key elements for streamlined manufacturing processes and consistent product quality.

Learn more about our jig and fixture services.

Gauge Making

Mahuta Tool excels in designing and manufacturing precision gauges used across various applications. Our gauges, a testament to our position in the precision tool and die industry are crafted to provide top-notch precision and reliability, essential for achieving accurate measurements and manufacturing process consistency.

Learn more about our gauge-making services.

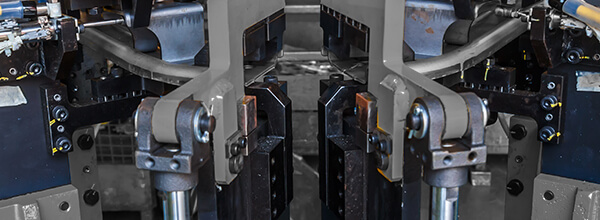

Metal Stamping

Our proficiency extends to a broad spectrum of fast-turnaround metal stamping services. With technical expertise and state-of-the-art machinery, we deliver metal stamped components that meet our client's exact specifications.

Learn more about our metal stamping services.

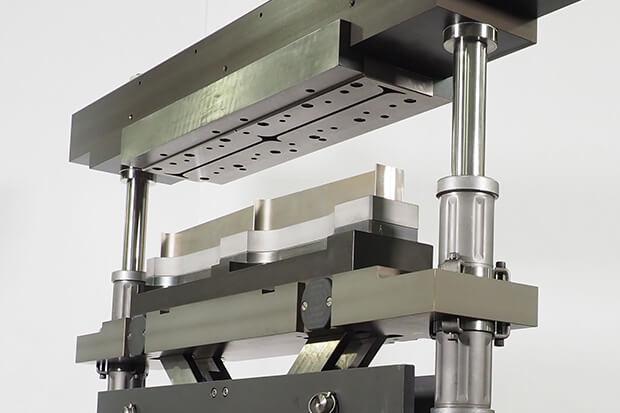

Die Manufacturing

Our die manufacturing capabilities include diverse types like:

- Coining dies

- Trim dies

- Forming dies

- Draw dies

- Blanking dies

- Secondary dies

- Hand transfer dies

- Swaging dies

Our die manufacturing services also include single hit, progressive, and transfer stamping, providing versatility to meet your specific project requirements.

Why Choose Mahuta Tool for Tool and Die Manufacturing Services?

Mahuta Tool has an ISO-9001:2015 certified quality management system. We are also a Mil-Spec-compliant establishment, reflecting our commitment to impeccable engineering, cutting-edge design, and ethical business practices. Trusted by the Aerospace and Defense Certified Manufacturing Services sector, our tool and die products are widely used in the manufacture of drawn shells, perforated shapes, pans and channels, along with embossing and engraving.

We pride ourselves on our swift turnaround times and competitive pricing. Specializing in prototype, specialty, and low-volume manufacturing, we also provide emergency and rush services. Trust Mahuta Tool for precision tool and die work that delivers exceptional value for your investment.

Precision Tool & Die Shop For Every Industry

We serve industries across the United States and Canada. Some of the industries we love to serve include:

- Aerospace

- Automotive

- Electronics

- HVAC

- Machine Tool

- Medical

- Military

- Mining

- Oil Field

- Power Generation

Learn more about the industries we serve for tool and die services.

Contact Mahuta Tool - Tool & Die Manufacturing

Eager to learn more about our tool and die services or request a quote? Connect with Mahuta Tool online or dial 888-686-4940. Start your journey to precision, quality, and efficiency in manufacturing with us. Your trusted tool and die shop awaits your call.