Wisconsin CMM Measuring & Inspection Services

Contact & Non-contact CMM Inspection Services for Tooling, Prototypes, and Production Parts

CMM Dimensional Inspection Services

Mahuta Tool is your go-to provider for local CMM (Coordinate Measuring Machine) services, bringing accurate and reliable CMM measurement services to the Milwaukee area. Specializing in the science of metrology and CMM inspection, we deliver outstanding precision and repeatability, reinforcing our status as a trusted leader in dimensional inspection services.

CMM Inspection Capabilities

Our diverse range of CMM inspection services includes:

- Dimensional Metrology: Leveraging advanced CMM technology, we ascertain exact measurements of parts to certify their ideal fit and function in the end application.

- Profile Metrology: We assess the geometric profile of components to ensure appropriate assembly and performance.

- Angularity Measurement: Our CMM inspection checks specific angularity on parts, essential for guaranteeing alignment and assembly.

- Depth Mapping: Utilizing CMM, we produce meticulous depth maps, vital for part interactions and clearances.

- First Article Inspection: We verify the initially produced unit against specified dimensions before commencing full-scale production.

- Third-Party Metrology: We offer third-party CMM inspection to validate the precision of parts produced by others, providing unbiased verification. Our CMM service caters to both contact and non-contact measurement requirements. Our contact CMM inspection manages dimensions up to 19.7” x 27.6” x 15.7”, while our non-contact (video) CMM inspection accommodates measurements up to 12.4” x 12.4” x 9.8”.

Whether you need contact or non-contact measurement, our CMM service is equipped to meet diverse requirements. Our contact CMM inspection accommodates dimensions up to 19.7” x 27.6” x 15.7”, while our non-contact CMM inspection handles measurements up to 12.4” x 12.4” x 9.8”.

Beyond Wisconsin: Serving the US with CMM Inspection Services

From local businesses to our extensive partnerships nationwide and in Canada, our reputation as a reliable provider of CMM inspection services continues to grow.

Operating as an experienced CNC machining shop, our focus lies in achieving the utmost precision, and delivering custom manufacturing services per your unique needs. Our CMM measurement services uphold this commitment, enabling us to meet and often surpass stringent industry standards.

CMM Measuring Services Across the United States

Mahuta Tool Corp. excels in CMM Measuring services for clients in Wisconsin, Illinois, Michigan, Indiana, Minnesota, Iowa, Missouri, North Dakota, South Dakota, and Ohio. Our commitment to precision ensures accurate measurements in all our tooling projects. Contact us today for a quote or more information on our CMM Measuring capabilities.

CMM Inspection for Minutely Detailed Parts

The power of our CMM inspection services lies in the ability to accurately measure small, intricate parts, which can be especially susceptible to damage. Our non-contact CMM measures such delicate components without causing harm while maintaining the precise dimensions needed for accurate reproduction or quality assurance.

Contact Mahuta for Accurate CMM Inspection Services

Whether you're seeking a reliable provider for dimensional inspection services, CMM service for complex components, or a partner to handle third-party CMM inspections, Mahuta Tool is prepared to meet your requirements with precision and professionalism. Contact us online today for a quote on our CMM inspection services, and take the first step towards accuracy, quality, and efficiency in your manufacturing processes.

Contact Mahuta Tool online for a CMM inspection quote or more information.

Faro Arm, Gage Plus CMM

The Faro Gage arm is a highly accurate 3D gauge for smaller parts. It’s’ built with temperature and overload sensors that allow it to detect and react to change. With an internal counterbalancing system that limits user fatigue, this machine maximizes accuracy and allows your team to produce quality results every time.

24" Radius

Mitutoyo S 574 CMM

This machine is capable of performing very accurate measurements at high speed. With Mitutoyo’s world-renowned ABS scale, the S574 has a high resistance to environmental conditions and does not require homing to be performed upon startup.

19.7" x 27.6" x 15.7"

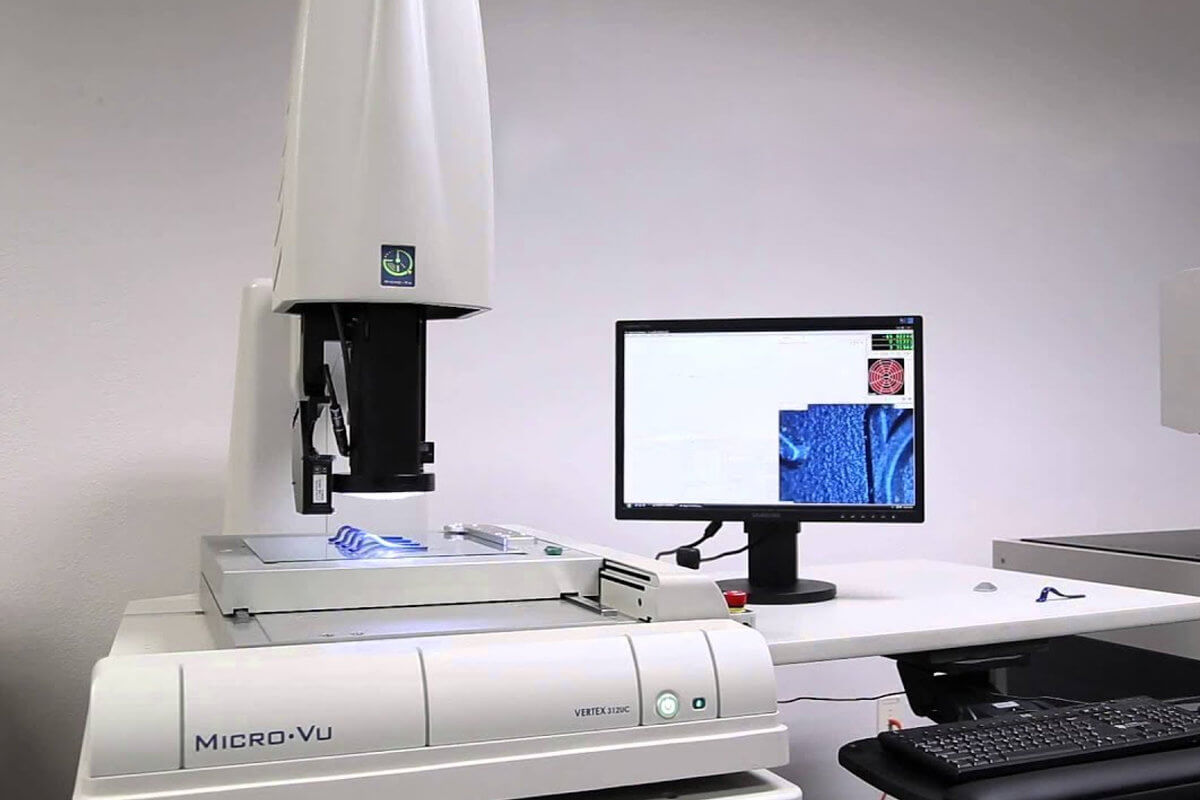

Micro-VU Sol 312 Vision System

The Sol Vision System implements new technologies to provide high speed and reliable accuracy on an affordable measuring machine. Thanks to a programmable 19.5x zoom, non-linear compensation, advanced lighting, and part program compatibility, the Micro-VU Sol 312 is an industry leader in its class.

315mm x 315mm x 250mm

Mitutoyo Contracer CV-2100M4 Contour Inspection System

The Mitutoyo Contracer CV-2100M4 provides an excellent combination of high accuracy and outstanding operability for increased support of a wide variety of measurement tasks. This machine effectively eliminates bothersome setup operations such as magnification switching and calibrations required for analog instruments.

100mm x 25mm

Rockwell Hardness Tester

Rockwell's Hardness Tester is the industry leader in hardness testing. It’s designed to meet the toughest challenges like clamping large parts, operating in poor environments, and testing in high volume—and with less operator skill required. A test cycle can be performed in as little as 4 seconds!