Custom Bronze Alloys Machining Services

Mahuta Tool provides bronze alloys machining services to companies nationwide, offering high-quality, precision components for marine, aerospace, energy and other demanding industries. Our advanced CNC and Wire EDM capabilities allow us to produce complex parts with exceptional accuracy and repeatability. We partner with clients across the U.S. and Canada to deliver components machined to exact performance requirements. Request a quote today for precision bronze alloys machining services.

Bronze Alloy Machining and Wire EDM Capabilities

Machining bronze requires an understanding of its varied compositions, from aluminum bronze’s rugged wear properties to phosphor bronze’s exceptional fatigue resistance. Our shop is equipped to machine a full range of bronze alloys and more, delivering functional and durable components.

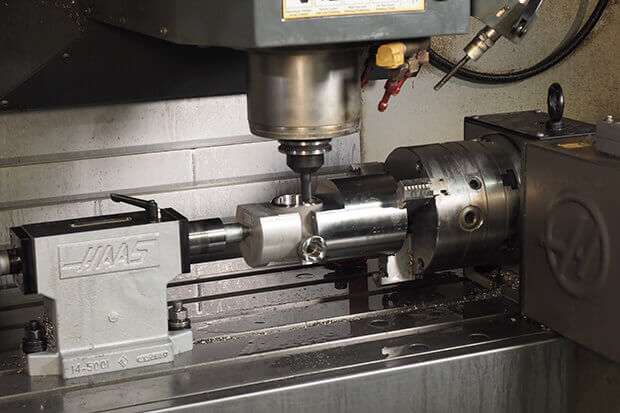

Using advanced CNC milling, turning, multi-axis machining, OD grinding and prototyping, we produce precision parts for both small and large production runs. For intricate or high-tolerance features, our Wire EDM services create clean edges and detailed profiles without altering the alloy’s integrity.

Bronze Alloys We Machine

Mahuta Tool offers machining services for multiple alloy grades. Each formulation has distinct properties suited to specific industrial applications:

| Alloy Type | Composition | Key Characteristics | Common Uses |

|---|---|---|---|

| Silicon Bronze | Copper, Silicon (≤6%), Zinc | High strength, easily pourable, corrosion-resistant, attractive surface finish | Pumps and valve parts |

| Phosphor Bronze (Tin Bronze) | Copper, Tin, Phosphorus | Wear-resistant, tough, low-friction, fine-grain | Anti-corrosive equipment, springs and electrical components |

| Aluminum Bronze | Copper, Aluminum | High strength, corrosion & tarnish resistant | Oil, petrochemical and water supply industries |

| Manganese Bronze | Copper, Manganese, Zinc, Aluminum, Iron | Flexible, impact-resistant, saltwater corrosion-resistant | Valve and pump parts, nuts, bolts, gears and boat propellers |

| Bearing Bronze | Copper, Lead, Tin, Zinc | Low friction, ideal for high-wear areas | Bearings and bushings |

| Copper-Nickel Bronze (Cupronickel) | Copper, Nickel | High thermal stability, durable, saltwater corrosion resistant | Marine equipment, ship hulls, valves, pumps and electronics |

Available Machining Services:

- CNC milling for accurate shaping and high-quality surface finishes

- CNC turning for precise round or cylindrical parts

- Multi-axis machining for complex designs in fewer setups

- CNC OD grinding for achieving precision diameters

- Prototyping for pre-production testing and refinement

- Wire EDM for intricate contouring without heat distortion

Industries Using Bronze Machining

Bronze alloys see widespread use in industries where durability, corrosion resistance and smooth operation are essential:

- Marine: propellers, bearings and underwater hardware

- Construction: bushings, wear plates and structural fittings

- Aerospace: control system components and bearing surfaces

- Military and Defense: ruggedized marine and mechanical components

- Electronics: conductive, corrosion-resistant connectors

- Power Generation: turbine bushings, pump housings and valve parts

- Medical: components requiring corrosion resistance and biocompatibility

Why Partner with Mahuta Tool for Bronze Alloys Machining

Bronze’s diverse alloy families require different cutting speeds, tooling strategies and finishing techniques to achieve optimal performance. Our machinists bring the expertise to match the right process to the right alloy, whether you need aluminum bronze for wear resistance or cupronickel bronze for marine service.

From our Wisconsin facility, we serve customers throughout the U.S. and Canada with components tailored to exact specifications. Our ISO 9001:2015 certified processes, precision equipment and dedication to craftsmanship result in consistent, high-performance parts. See our portfolio of completed projects for examples of our work.