Aluminum Machining Services near Milwaukee, WI

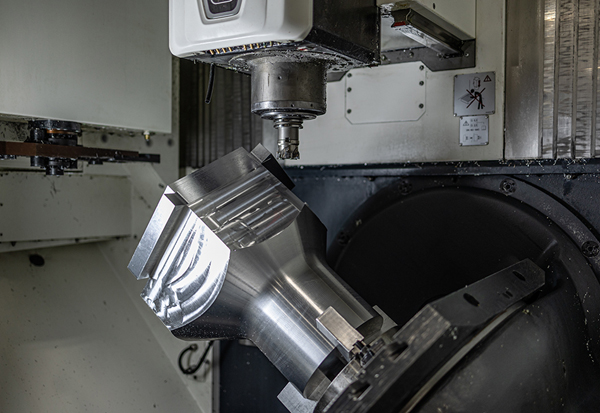

Mahuta Tool provides aluminum machining services for industries requiring lightweight, corrosion-resistant and high-strength components. Our advanced CNC and Wire EDM capabilities allow us to produce complex aluminum parts with exceptional accuracy, smooth finishes and repeatable quality. Serving clients across the U.S. and Canada, we specialize in high-performance aluminum parts engineered for demanding applications. Contact us today for a quote on precision aluminum machining services.

Aluminum Machining and Wire EDM Capabilities

Aluminum’s excellent formability, high strength-to-weight ratio and corrosion resistance make it a versatile material for structural and precision components. Our team machines aluminum parts using advanced CNC milling, turning, multi-axis machining, OD grinding and prototyping techniques to meet strict tolerances and surface finish requirements.

When projects call for intricate features or tight-tolerance profiles, our Wire EDM services provide clean, burr-free cuts without heat damage. We work with a variety of aluminum grades, from common alloys to specialty aerospace-grade materials, tailoring our approach to the performance needs of each part.

Our Aluminum Machining Capabilities Include:

- CNC milling for accurate shaping and high-quality surface finishes

- CNC turning for precision cylindrical components

- Multi-axis machining for complex geometries and reduced setups

- CNC OD grinding for fine dimensional control

- Prototyping for pre-production testing

- Wire EDM for intricate contouring without heat distortion

Machined Aluminum Components for Critical Industries

Aluminum’s light weight, high conductivity, strength and corrosion resistance make it an ideal choice for a wide range of applications, including:

- Aerospace: structural assemblies, interior brackets and landing gear parts

- Automotive: lightweight engine components, body panels and transmission housings

- Electronics: precision housings, conductive enclosures and heat sinks

- Marine: mast hardware, corrosion-resistant fittings and hull framing

- Power Generation: solar panel frames, wind turbine components and electrical bus bars

- Construction: steps, platforms and framing elements for heavy-duty equipment

- Medical: lightweight surgical tools, equipment housings and non-magnetic fixtures

Why Choose Mahuta Tool for Aluminum Machining Services

Aluminum machining requires precise tooling strategies to achieve tight tolerances while maintaining surface quality. With its high strength-to-weight ratio, excellent conductivity and ability to be anodized for enhanced corrosion resistance, aluminum is ideal for high-performance applications where weight matters.

Mahuta Tool’s experience covers high-volume production and custom one-off projects with aluminum and other materials. We provide aluminum machining for industries across the U.S. and Canada, delivering parts designed for strength, performance, and reliability. Our ISO 9001:2015 certified processes, advanced machining capabilities and attention to detail guarantee every component meets your specifications. View our portfolio of completed projects for examples of our aluminum machining work.