Specialized Copper Machining Services

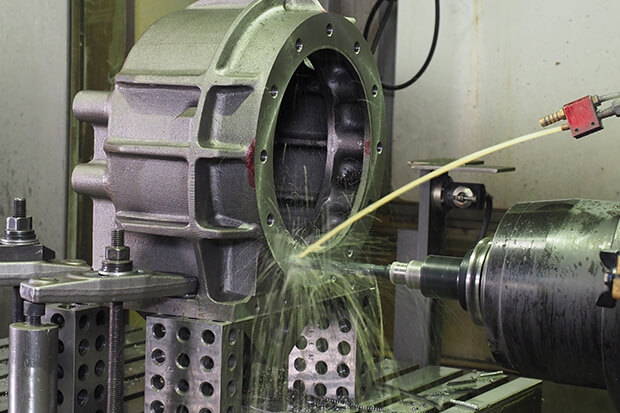

Mahuta Tool offers precision copper machining services for industries reliant on superior electrical and thermal conductivity. Our CNC and Wire EDM capabilities allow us to produce complex copper components with exceptional accuracy, clean finishes and consistent performance. Serving clients across the U.S. and Canada, we manufacture copper parts for electrical, thermal and structural applications where material performance is critical. Request a quote today for expert copper machining services.

Advanced Copper Machining and Wire EDM

Copper’s softness and ductility make it highly workable and can cause tool wear, burring and dimensional distortion if not machined with the proper techniques. Mahuta Tool uses optimized tooling, precise feeds and speeds and specialized workholding to deliver copper parts tailored to exacting standards.

We machine copper and more complex materials using CNC milling, turning, multi-axis machining, OD grinding and prototyping for functional and aesthetic components. For intricate or heat-sensitive profiles, our Wire EDM services provide burr-free cuts without affecting copper’s conductivity or surface quality.

Our Copper Machining Capabilities Include:

- CNC milling for accurate shaping and smooth surface finishes

- CNC turning for precise cylindrical and rotational parts

- Multi-axis machining for complex geometries in fewer setups

- CNC OD grinding for tight dimensional control and fine finishes

- Prototyping for testing and design refinement

- Wire EDM for precise contouring without altering conductivity

Industries and Applications for Copper Machining

Copper’s outstanding electrical and thermal performance, corrosion resistance and machinability make it valuable across a wide range of industries:

- Electronics: electrical contacts, terminals and heat sinks

- Power Generation: bus bars, power transmission components and grounding systems

- Aerospace: conductive hardware and heat management components

- Medical: non-magnetic surgical instruments and imaging system components

- Marine: corrosion-resistant fittings and heat exchanger tubing

- Industrial: tooling inserts, molds and and wear components

Why Work with Mahuta Tool for Copper Machining

Though copper’s ability to carry electrical current and transfer heat is unmatched, machining it to precision tolerances requires more than just standard cutting tools. Mahuta Tool’s team has experience producing copper components with tight dimensional requirements, critical conductivity and surface integrity.

From our Wisconsin facility, we serve customers across the U.S. and Canada with copper machining services tailored to specialized applications. Our ISO 9001:2015 certified processes, advanced CNC equipment and quality-first approach deliver reliable components made for consistent performance. Explore our portfolio of completed projects for examples of our copper machining work.