Custom Metal Finishing Service with Nationwide Shipping

Metal Finishes That Do More Than Look Good

For some machining jobs, the finish is the aesthetic cherry on top of a quality CNC machined part. At Mahuta Tool, whether your product’s finish is just for looks or serves a critical function, we treat every metal finishing job as if it is crucial for your application. Our shop uses advanced techniques and technologies to apply a durable and attractive metal finish.

Mahuta’s finishing application techs are experienced in applying various coatings to a range of base materials for aesthetics, corrosion resistance and friction reduction. If you're not sure what would be the best finish for your part, we can assist you in selecting one that will meet your criteria and perform to exceed your expectations.

Why Choose Mahuta Tool for Metal Finishing?

- Industry Expertise: With a diverse range of industries under our belt, we have a deep understanding of the unique challenges and demands of each sector. We leverage this expertise to create perfect metal finishes that perform flawlessly in their intended applications.

- Material Selection: We know that the choice of material can significantly impact the performance and cost-effectiveness of a project. Our experts guide you through the process, helping you select the ideal metal that meets your project's specific requirements.

- Environmental Considerations: We take into account the operating environment of your components, ensuring that they can withstand extreme temperatures, corrosive substances, or high levels of moisture.

- Precision: Precision is paramount in CNC machining, and our designs are meticulously created to meet tight dimensional tolerances.

- Optimal Weight and Strength: Balancing weight and strength is crucial in many applications. We assist you in choosing materials that strike the perfect balance.

- Cost-Effective Solutions: We aim to provide you with materials that not only meet your project's technical demands but also do so in a cost-effective manner.

Available Metal Finishes For Every Industry

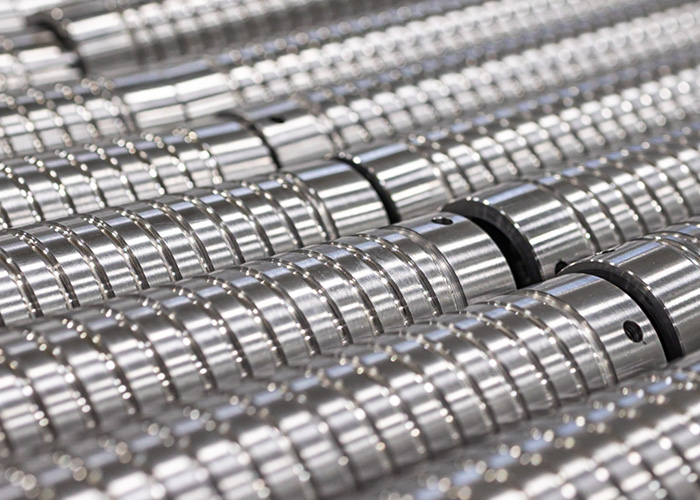

As-Milled

As-milled or 'mill finish' is the texture of the metal after extrusion, molding, or tooling. Mill-finishing has no protective qualities, which makes it more suited for materials that don't rust, corrode or tarnish such as aluminum.

Metal Brush

Brushed metal is an attractive option for decorative components. For automotive, appliance parts, a brushed surface looks great. Brushed stainless steel, aluminum and nickel are very popular for applications where end-users will see exposed metal.

Bead Blast

Bead blasting utilizes glass bead particles to produce a uniform, low-sheen finish on machined metal parts. Unlike sandblasting, bead blasting results in a lower surface profile. Bead blasting is a great way to smooth over minor surface imperfections or tooling marks.

Powder Coated

Powder coating finishes are one of the best ways to protect finished metal products from corrosion. By creating a hard shell around the material, powder coating shields machined parts from exposure to moisture and atmospheric corrosives.

Anodized

In machined aluminum, titanium, or magnesium an anodized finish provides wear resistance, which can be maximized with a sealing process. Anodized parts can be customized with various colors for decorative or color-coding purposes.

Other Metal Finishes

Need a specialized finish on your CNC machined parts? Get in touch with us and tell us about your project. We can apply coatings beyond those listed above. Whether it's a finish we apply regularly or one that's done just for your project, you can trust that when you send something to Mahuta, you'll get it done right.

Which Metal Finish is Right For Me?

Choosing the right metal finish for your CNC machined parts can greatly impact their performance, aesthetics, and cost-effectiveness. To make an informed decision, you need to consider the specific requirements of your project.

The Mahuta Tool team can provide guidance tailored to your project. With extensive experience in CNC machining and finishing processes, we can assist you in choosing the best finish for your CNC machined parts. Whether you prioritize functionality, protection, or aesthetics, Mahuta Tool can help you achieve your project goals.