CNC Turning Services in Wisconsin

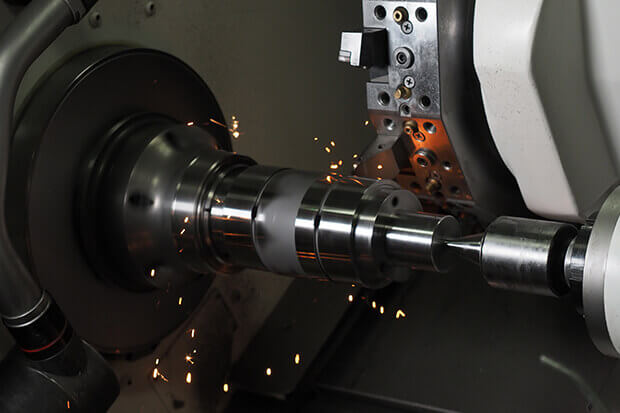

Mahuta Tool provides precision CNC turning services, with proven horizontal and vertical turning capabilities. Our CNC machining team produces accurately turned parts for manufacturers across Wisconsin and North America using modern CNC lathes built for reliability and repeatability. From short runs to production support, our CNC turning service adapts to complex part requirements and demanding timelines. Contact us today to request a quote.

Mahuta Tool provides precision CNC turning services, with proven horizontal and vertical turning capabilities. Our CNC machining team produces accurately turned parts for manufacturers across Wisconsin and North America using modern CNC lathes built for reliability and repeatability. From short runs to production support, our CNC turning service adapts to complex part requirements and demanding timelines. Contact us today to request a quote.

CNC Horizontal Turning

Mahuta Tool offers CNC horizontal turning in Wisconsin for components weighing up to 950 lbs., measuring up to 44" in length and 25" in diameter. Our CNC horizontal turning centers also handle parts as small as 1/8" wide while holding tight tolerances. Live tooling and 3-axis capability support internal and external threading, knurling, profiling and additional machining operations within a single setup.

CNC Horizontal Turning Applications

We provide CNC horizontal turning services for:

We provide CNC horizontal turning services for:

- Machine components

- Engine components

- Turbine components

- Hydraulic components

- Construction equipment

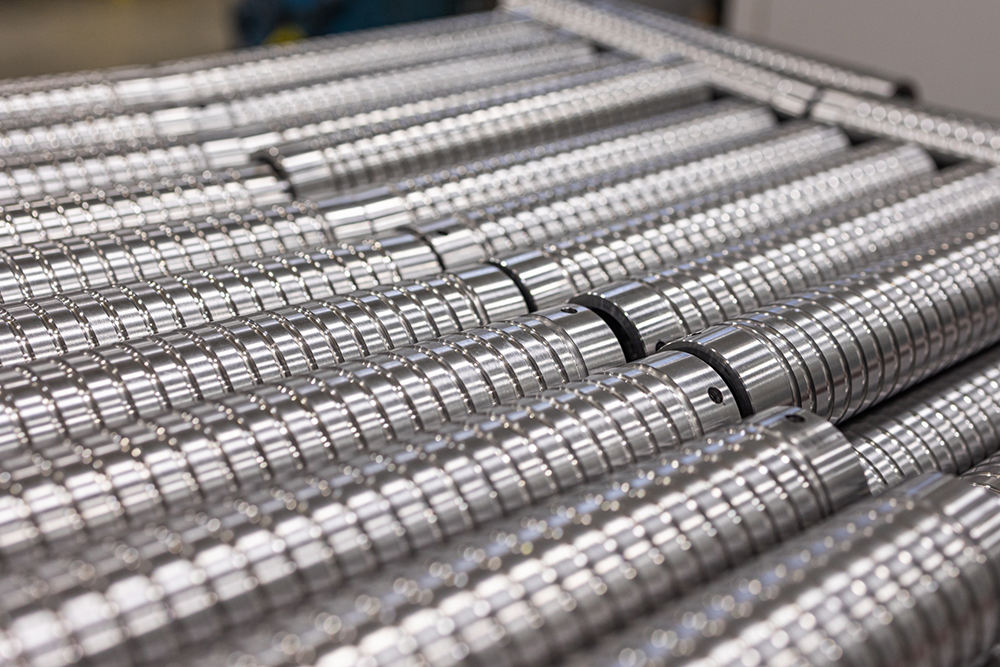

- Shafts

- Forgings

- Valves

- Pins

- Thread rod

- Fasteners

- Spindles

- Sockets

- Bushings

- Custom Nuts & Bolts

- Spacers

- Fittings

- Standoffs

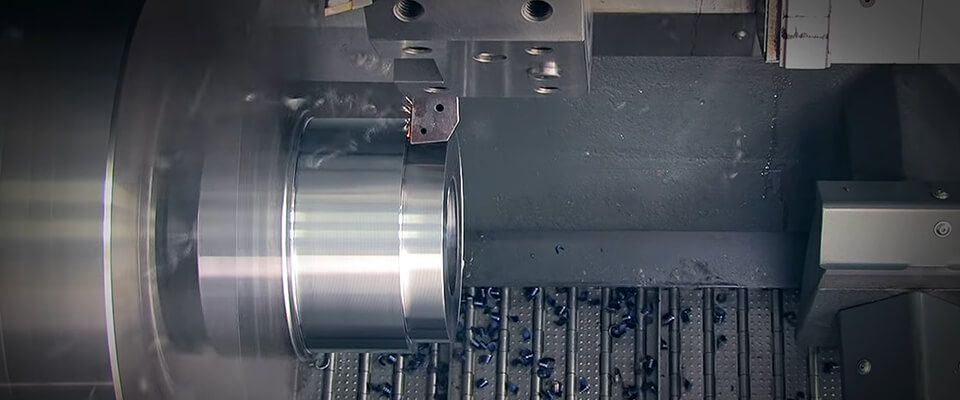

CNC Vertical Turning

Our CNC vertical turning services in Wisconsin support large, heavy components across various industries, including construction, agriculture, aerospace and defense. Our CNC vertical turning machines produce precision parts up to 28" long with diameters up to 36" and weights up to 20,000 lbs. Our machining operations include contour turning, straight turning, internal forming, counterboring and pocketing.

CNC Vertical Turning Applications

We provide CNC vertical turning services for:

- Machine components

- Turbine components

- Construction equipment

- Custom Nuts & Bolts

- Forgings

- Fasteners

- Bushings

- Spacers

- Fittings

- Standoffs

Applications of Our CNC Turning Services

- Aerospace: Precision parts for aircraft and spacecraft.

- Construction: Durable components for heavy machinery.

- Energy: High-tolerance parts for power generation equipment.

- Automotive: Engine and drivetrain components with tight specifications.

Equipment for CNC Lathe Services

We use Haas, Okuma, Nardini and Econo Master lathes featuring bar feed capability and large swing capacity for high-precision CNC turning capabilities. We produce forgings, shafts, bushings, fixtures, fittings and construction equipment components across prototype and production programs. Additional services include reverse engineering, assembly, finishing, CAD modeling and CAM programming.

Mahuta Tool machines alloy steels, stainless steel, brass, iron and more challenging materials. We accept drawings in SolidWorks, AutoCAD, STEP, PDF and DXF formats.

HAAS SL-40 CNC Lathe

The ST-40 is a large-frame lathe with a large workload capability. Its high-performance turning centers were designed to provide setup flexibility, high thermal stability, and superb rigidity. This machine offers some of the best value in its class.

25.5" dia. x 40"

Haas SL-30BB CNC Lathe

The Haas SL-30BB is a durable and reliable machine that ensures quality and speed of production for all of its products. Like all Haas CNC machines, the SL-30BB offers some of the best value for money in its class.

17" dia. x 30"

Bar Feeder

(2) Okuma LB3000EX-11/500

This lathe is one of the largest Okuma produces. It comes equipped with a high-power, high-torque PREX motor to allow high-quality machining from high-speed cutting. The open-architecture OSP-P control makes this machine easy to operate and convenient to integrate with other peripheral equipment.

16.14" dia. x 20"

Okuma Heritage Es-L8Mil CNC

8" dia. x 10"

LIVE TOOLING

Bar Feeder

Okuma Genos

This lathe presents an affordable entry-level lathe that is anything but basic. The Genos provides stability, rigidity, and accuracy for a wide variety of applications.

11.81" dia. x 43.31"

LIVE TOOLING

Okuma V760EX

The Okuma V760EX is capable of performing powerful, heavy-duty cuts and has a vertical orientation, making this the ideal platform for machining small, thin or odd-shaped workpieces. The box-type base and column ensure stable and accurate cutting for high-quality products with tight tolerances.

29.92" dia. x 31.50"

Okuma V920EX

The Okuma V920EX vertical lathe provides a reliable solution for machining thin and unconventional workpieces with stable precision. Equipped with a sturdy box-type base and column, the lathe's headstock and flange construction minimize thermal deformation and vibration, guaranteeing dependable and accurate cutting.

36.22" dia. x 28.88"

Why Choose Mahuta Tool for CNC Turning Services?

- Short Lead Times: Our CNC turning service prioritizes schedule alignment to keep production moving.

- Custom Machining Solutions: Programs adapt to part geometry, material selection and production scope.

- ISO 9001:2015 Certified Quality System: Mahuta Tool operates under an ISO 9001:2015 certified quality management system supporting consistent machining performance.

- Expert Technicians: Machinists bring extensive turning experience to complex projects requiring precision execution.

CNC Turning Services Across the United States

Mahuta Tool provides CNC turning services for customers throughout Wisconsin, Illinois, Michigan, Indiana, Minnesota, Iowa, Missouri, North Dakota, South Dakota and Ohio. Our CNC horizontal turning and CNC vertical turning services support manufacturers across multiple industries with dependable machining performance.