Durable Tungsten Machining Services

Mahuta Tool delivers custom tungsten machining services for industries demanding extreme strength, density and high-temperature performance. We produce tungsten components with unmatched dimensional accuracy and repeatable quality through our advanced CNC and Wire EDM capabilities. Serving clients across the U.S. and Canada, we specialize in machining tungsten for demanding applications where conventional materials cannot perform. Request a quote today to discuss your tungsten machining needs.

Tungsten Machining and Wire EDM Capabilities

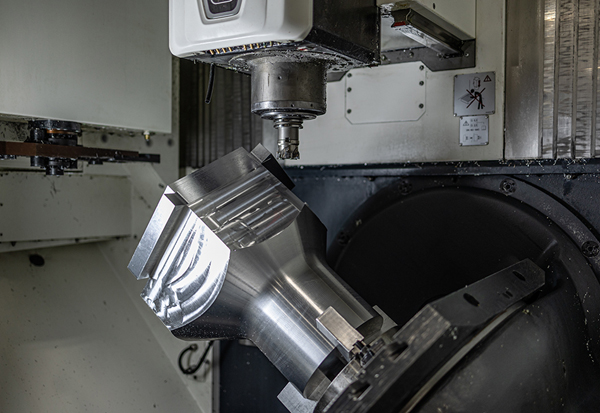

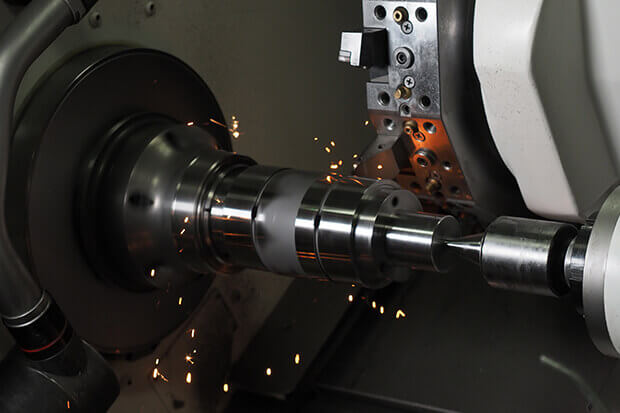

Tungsten is known for its exceptional density, hardness and ability to withstand extreme heat. Our machinists combine advanced tooling strategies with CNC milling, turning, multi-axis machining, OD grinding and prototyping to achieve precise, high-quality results.

For intricate or ultra-tight-tolerance parts, our Wire EDM services deliver clean, heat-free cuts to preserve material integrity and prevent microcracking. We work with pure tungsten and more complex materials, tailoring our machining approach to specific performance requirements.

Our Tungsten Machining Capabilities Include:

- CNC milling for complex geometries and precision shaping

- CNC turning for accurate cylindrical and rotational components

- Multi-axis machining for intricate profiles and reduced setups

- CNC OD grinding for fine dimensional accuracy and smooth finishes

- Prototyping for design testing and refinement

- Wire EDM for detailed contouring without introducing heat damage

Industries and Applications for Tungsten Machining

Tungsten’s extreme density, hardness and heat resistance make it an ideal material for critical, high-stress applications across multiple industries:

- Aerospace: high-temperature turbine components, counterweights and radiation shielding

- Medical: radiation shielding, surgical tools and precision medical components

- Military and Defense: armor-piercing projectiles, kinetic energy penetrators and guidance systems

- Power Generation: nuclear reactor components and heat exchanger parts

- Machine Tooling: dies, punches and wear-resistant tooling

- Electronics: electrical contacts, heat sinks and x-ray tube components

Why Choose Mahuta Tool for Tungsten Machining

Tungsten’s hardness and brittleness require specialized machining expertise to prevent chipping, cracking or dimensional inaccuracy. Though many machining shops avoid working with tungsten, Mahuta Tool has the experience, equipment and process controls to deliver tight-tolerance tungsten parts for performance in harsh environments.

We serve clients across the U.S. and Canada from our Wisconsin facility with custom tungsten machining services. Our ISO 9001:2015 certified processes, advanced CNC technology and dedication to precision result in reliable, high-performance components. See our portfolio of completed projects for examples of our work.