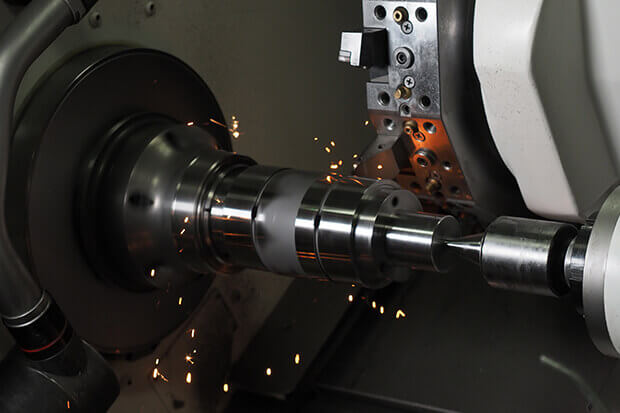

Precision Cobalt Machining Services

Mahuta Tool delivers precision cobalt machining services for industries demanding extreme strength and heat resistance. Our CNC and Wire EDM capabilities produce complex cobalt-alloy components with unmatched accuracy, durability and consistency. Serving clients across the U.S. and Canada, we specialize in high-performance parts built to thrive in the harshest environments. Contact us today to request a quote on custom cobalt machining services.

Cobalt Machining and Wire EDM Services

Our team uses advanced CNC milling, turning, multi-axis machining, OD grinding and prototyping processes to machine cobalt-alloy components with exceptional precision. For intricate geometries or ultra-tight tolerances, our Wire EDM services provide unmatched accuracy without generating excessive heat, preserving cobalt’s high-performance characteristics.

Every part undergoes full CMM inspection and is manufactured under our ISO 9001:2015 certified processes. We excel at machining materials avoided by other shops, using custom tooling and proven strategies to achieve superior results.

Our Cobalt Machining Capabilities Include:

- CNC milling for complex geometries and precision contours

- CNC turning for small- and large-diameter parts

- Multi-axis machining for intricate shapes and reduced setups

- CNC OD grinding for dimensionally accurate surface finishes

- Prototyping for testing and refining part designs

- Wire EDM for precision cuts and complex contours without excessive heat

Machined Cobalt Components for Critical Industries

Cobalt alloys are valued for their extreme durability and ability to maintain performance at high temperatures. Cobalt is commonly machined for use in industries like:

- Medical: prosthetic hips, knees and dental prosthetics

- Aerospace: jet engine and gas turbine blades, rocket motor components

- Military and Defense: high-strength, heat-resistant components

- Marine: corrosion-resistant propulsion and structural components

- Construction: wear-resistant, high-stress parts for heavy machinery

- Electronics: components requiring magnetic and wear-resistant properties

- Power Generation: nuclear reactor parts and power plant equipment

Why Choose Mahuta Tool for Cobalt Machining Services

Cobalt-based superalloys deliver superior corrosion resistance, wear resistance and weldability while maintaining strength and stability at extreme temperatures. A higher melting point and resistance to thermal fatigue make cobalt alloys ideal for demanding applications and notoriously difficult to machine.

Mahuta Tool specializes in working with challenging materials like cobalt. Our team uses advanced tooling, precision strategies and ISO 9001:2015 certified processes to produce tight-tolerance, high-performance components others avoid. We serve clients across the U.S. and Canada, delivering parts built to excel in the most punishing environments with precision cobalt machining services. View our portfolio of completed projects to see examples of our work.