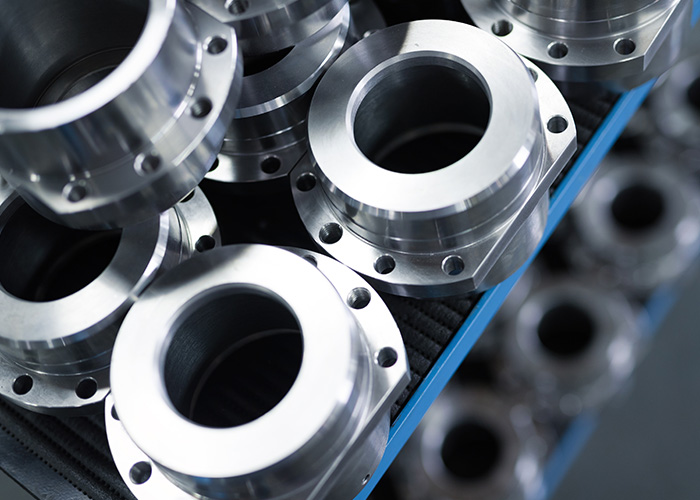

Alloy Steel Machining Services in Wisconsin

Mahuta Tool provides high-precision alloy steel machining services for manufacturers across Wisconsin and North America. Alloy steel brings the strength, toughness and wear resistance necessary for use in demanding mechanical environments. Our CNC machining and Wire EDM capabilities produce complex alloy steel components with tight tolerances, consistent finishes and dependable repeatability. Contact Mahuta Tool today for a quote on custom alloy steel machining services.

Alloy Steel Machining and Wire EDM Capabilities

Alloy steel requires stable setups, controlled toolpaths and experienced machinists to maintain dimensional accuracy across hardened or high-strength material structures. Our team uses alloy steel and other challenging metals to machine durable, high-performing prototypes and specialized components.

Mahuta Tool uses multi-axis CNC machining, OD grinding and Wire EDM to produce intricate geometries, refined surface quality and detailed internal features across alloy steel components built for industrial use.

Our Alloy Steel Machining Capabilities Include:

- CNC milling for accurate shaping and uniform surface integrity

- CNC turning for precise cylindrical geometry and threaded features

- Multi-axis machining for complex contours and reduced handling

- CNC OD grinding for refined round tolerances and finish control

- Prototyping for design validation and functional evaluation

- Wire EDM for complex profiles and burr-free detailing

Machined Alloy Steel Components for Demanding Industries

Mahuta Tool machines alloy steel components for performance-driven applications in industries across Wisconsin and nationwide.

- Automotive: drivetrain hardware, shafts and structural performance components

- Tooling: dies, fixtures and precision tooling assemblies

- Aerospace: brackets, support hardware and structural fittings

- Heavy Machinery: load-bearing housings, couplings and wear-resistant parts

- Construction: reinforced mechanical hardware and structural assemblies

- Mining: abrasion-resistant components and rugged machine parts

Why Choose Mahuta Tool for Alloy Steel Machining in Wisconsin

Machining alloy steel requires disciplined process control, stable fixturing and attention to thermal response across each operation. Mahuta Tool brings extensive experience producing alloy steel components for OEMs and industrial manufacturers throughout Wisconsin and North America.

Our ISO 9001:2015 certified processes, advanced CNC equipment and detail-driven approach support repeatable performance across prototypes and production orders. Explore our completed project portfolio today for examples of precision-machined alloy steel components.