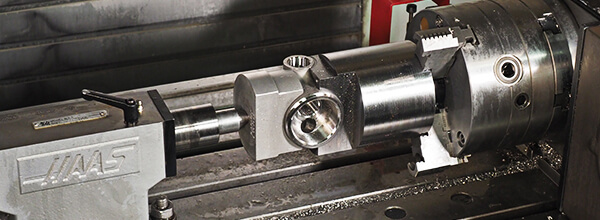

CNC Machining Services

Milwaukee CNC Machining Business Serving Wisconsin, the Midwest, & Beyond

Mahuta Tool provides custom CNC machining services for a wide range of industries. We routinely take on complex industrial machining work and rush jobs other CNC manufacturing centers can’t or won’t do. We can work from your CAD drawings, or you can have our in-house CAD design staff generate 2D CAD prints for use in CAM programming, CNC turning and CNC horizontal milling.

Located just outside of Milwaukee in Germantown, WI, Mahuta Tool serves clients throughout the Milwaukee area as well as all of the Midwest and as far away as Texas, New York, Oregon and Canada. Businesses have trusted Mahuta for more than two generations, relying on our fastidious commitment to excellence, and reputation for getting the job done right. We do precision work at fair prices with quick turnaround, and we strive to develop long-term partnerships with our customers.