Wisconsin Wire EDM Machining Services

Wisconsin Wire EDM Services for Precision Metal Parts Nationwide

Wisconsin Wire EDM Services for Precision Metal Parts Nationwide

Mahuta Tool provides Wisconsin’s top wire EDM machining Services for businesses throughout the US and Canada. Our experienced team, cutting-edge technology and dedication to customer satisfaction make us the preferred wire EDM CNC company in Wisconsin. We use wire EDM machining services to machine precision parts with short turnaround times for specialty machining, prototyping, low-volume manufacturing and more. Contact our team today for a quote on Wisconsin wire EDM machining services.

Fairly Priced Custom Wire EDM in Wisconsin with Fast Turnaround

Established in 1988, Mahuta Tool has built a distinguished reputation by providing precision CNC wire EDM parts and services to clients requiring short-run and low-volume production solutions.

Mahuta Tool is well-equipped to handle custom machining projects at our Wisconsin wire EDM CNC machine shop. Our advanced CNC machines and skilled technicians manufacture intricate parts to the highest standards with Wisconsin’s premier wire EDM machining services. We work closely with clients to understand their unique requirements and deliver tailored solutions through precision Wisconsin wire EDM machining services. Our multi-axis capabilities let us produce parts with close tolerances up to 27 ¾” by 15 ¾”.

Comprehensive Wire EDM Machining Services in Wisconsin

In addition to complex wire EDM CNC machining services, we offer reverse engineering, CAM programming and CAD design services in Wisconsin. All parts are inspected with a Coordinate Measuring Machine (CMM) for the highest quality and accuracy. Our ISO 9001:2015 certified quality management system and Mil-Spec compliance certification guarantee top-tier wire EDM machining services in Wisconsin for aerospace and defense industry work.

What is Wire EDM?

Wire Electrical Discharge Machining (Wire EDM) is an advanced CNC technique for creating precision CNC wire EDM parts by cutting metal with an electrified wire for exceptional accuracy and detail. The wire, typically made of brass or copper, is carefully guided through the workpiece. Controlled electrical sparks erode the material at contact, gradually shaping it into the desired form.

Our Wisconsin wire EDM machining services are unique and do not use mechanical force to cut the material. Instead, the electrical discharge energy removes minute amounts of material with each spark, allowing the wire to pass through the workpiece. Our wire EDM machining services produce precise cuts for intricate geometries, complex patterns and tight tolerances often unattainable with traditional machining methods.

Advantages of Wisconsin Wire EDM Machining Services

Wisconsin wire EDM machining services provide multiple benefits over traditional machining methods, making them vital in modern manufacturing. Wire EDM machining offers precision cutting for intricate parts and components with tight tolerances and enhances production efficiency through automation for faster turnaround times and cost-effectiveness. The process's flexibility allows complex geometries and various cutting angles while eliminating mechanical stress from direct contact. This leads to precision CNC wire EDM parts with superior structural integrity.

Our Wire EDM Metal Capabilities

Mahuta Tool offers Wisconsin wire EDM machining services for a wide range of metals, providing precision cuts and tight tolerances for complex parts. Our advanced CNC technology allows us to handle diverse materials and provide high-quality results for industries across North America. We perform wire EDM machining services on:

- Iron

- Carbon steel

- Carbide

- Stainless steel

- Magnesium

- Aluminum

- Tungsten

- Brass

- Copper

- Nickel

- Beryllium

Mahuta Tool's Wisconsin Wire EDM Machining Capabilities

Our Wisconsin wire EDM machining services set us apart from the competition. We specialize in taper cutting for parts with angular or contoured sides tailored to your requirements. Our cutting-edge machines process dense materials easily and produce top-notch results for the most demanding projects. Our equipment boasts an expansive travel range, granting us the flexibility to handle a diverse array of part sizes.

As a premier wire EDM CNC machine shop, we use sophisticated CNC technology to deliver unparalleled accuracy and precision across our Wisconsin wire EDM machining services. Known for our workmanship, competitive pricing and prompt turnaround times, we offer emergency support and accelerated wire EDM machining services in Wisconsin to meet time-sensitive demands.

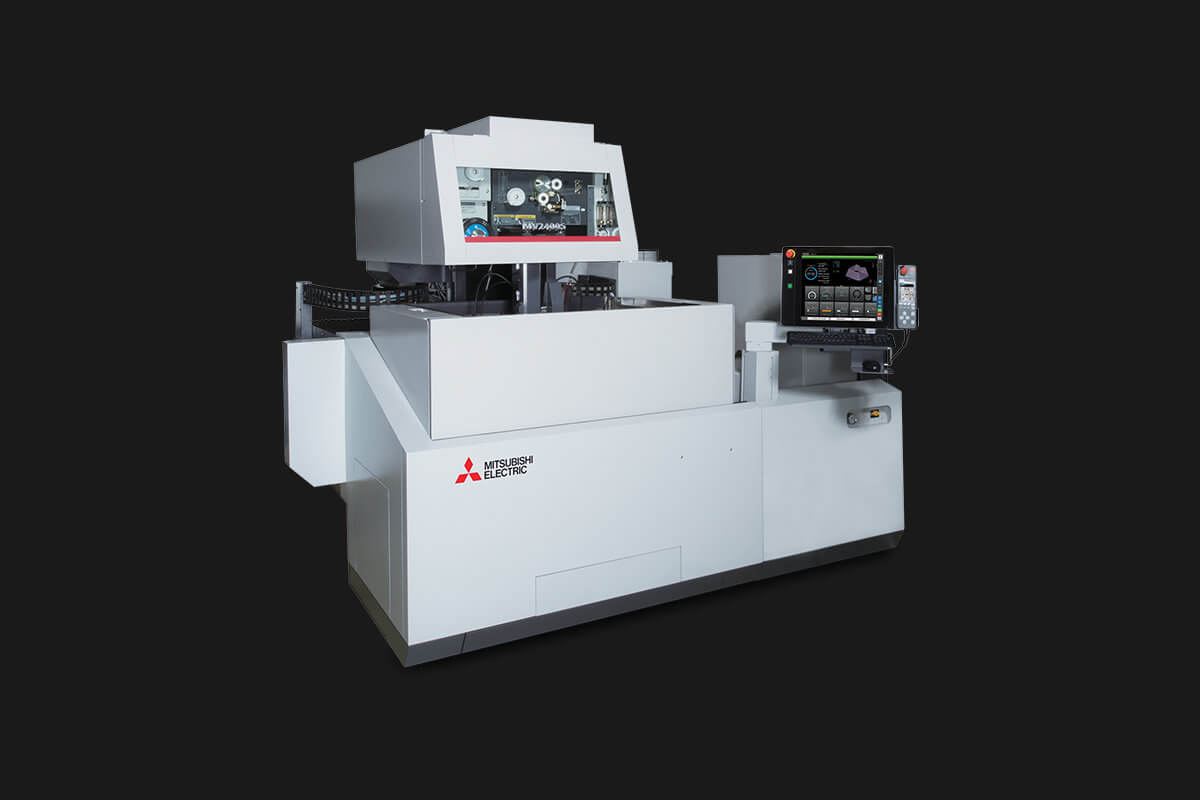

2 Mitsubishi MV-2400S's

This precise wire EDM uses the latest tech like the Mitsubishi M800 series control, providing an easier user interface than most models and helping our expert technicians easily achieve your exact specifications.

23.6" x 15.7" x 12.2"

Mitsubishi MV-1200

This well-rounded wire EDM is equipped with top-of-the-line auto-threading, internal machine communication and power supply technology for reduced operating costs.

15.7" x 11.8" x 12.2"

Charmilles EDM Drill

This EDM Drill (20 model) is a high-speed drill machine for drilling starting holes. The operator console is designed to make data input efficient and simple. Short circuit, temperature and liquid level sensors guarantee safe operation.

.03-3.0mm

Proudly Serving Wisconsin with Wire EDM Machining Services

Mahuta Tool provides precision wire EDM services throughout Wisconsin, including Milwaukee, West Bend, Madison, Green Bay, Kenosha, Racine, Appleton, Waukesha, Oshkosh, Eau Claire, Janesville, Wauwatosa, Fond du Lac and beyond.

If you're looking for a reliable and experienced Wisconsin wire EDM machining company, Mahuta Tool is here to help. We offer competitive pricing and unparalleled customer support. Our commitment to sound engineering, ethical business practices and innovative design lets us exceed your expectations and deliver high-quality, precision parts for your business.

To request a quote for our Wisconsin wire EDM CNC machining services, you'll need to send drawings of your part. We accept formats like .pdf, .dxf, AutoCAD, SolidWorks and STEP.