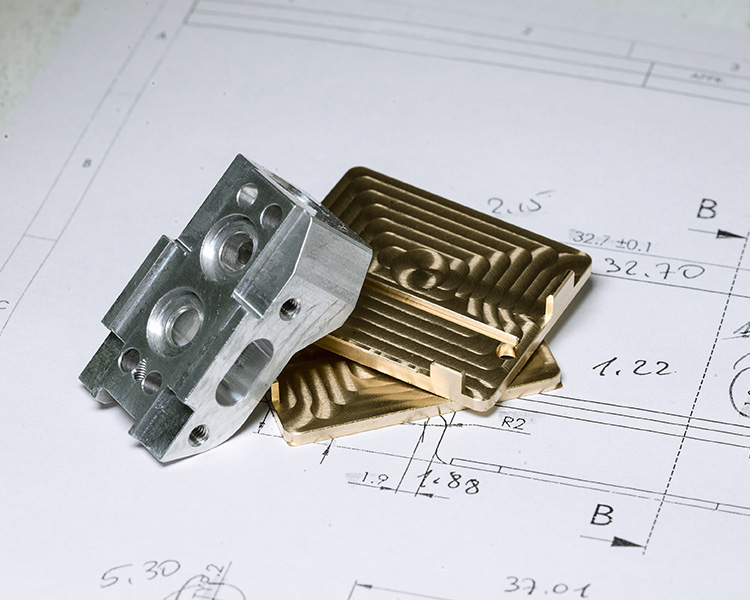

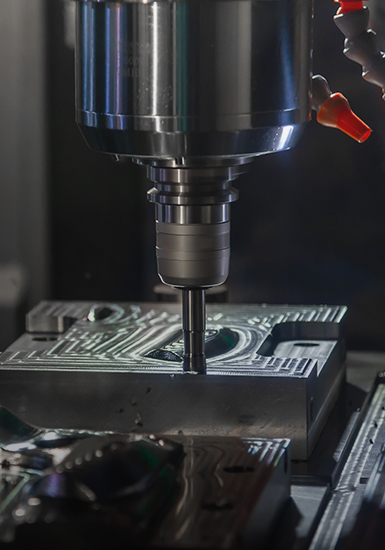

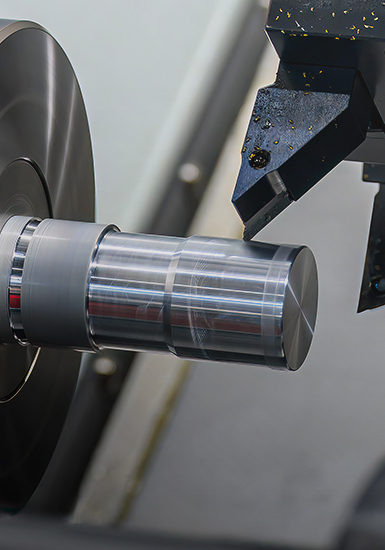

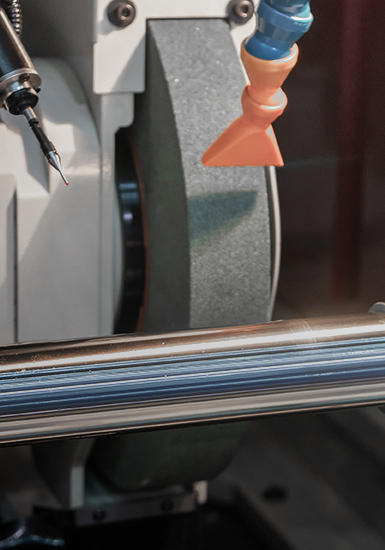

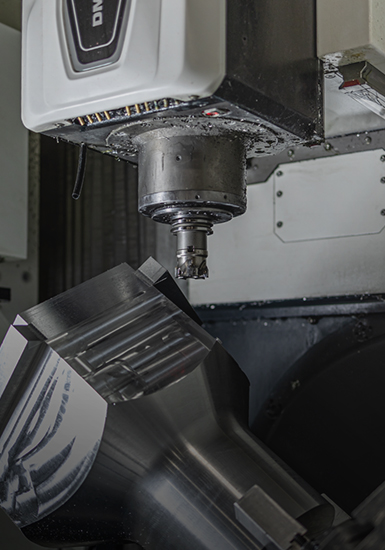

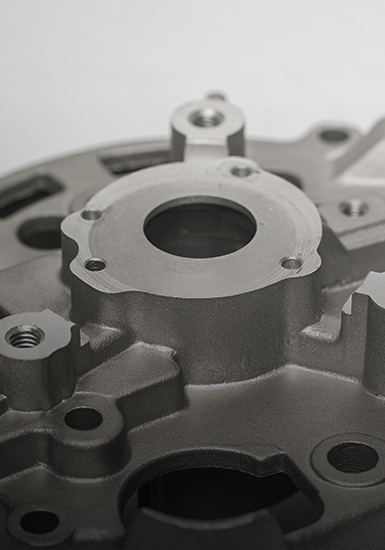

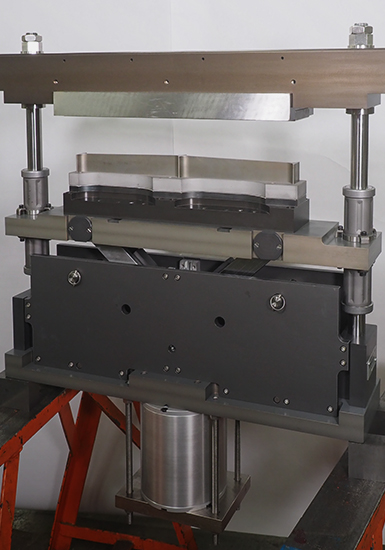

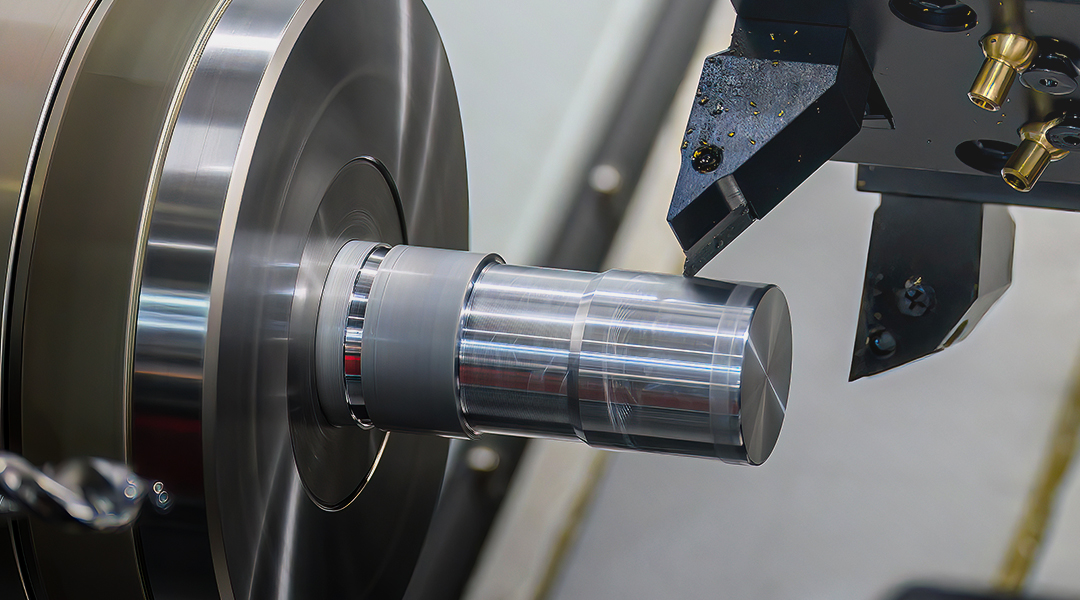

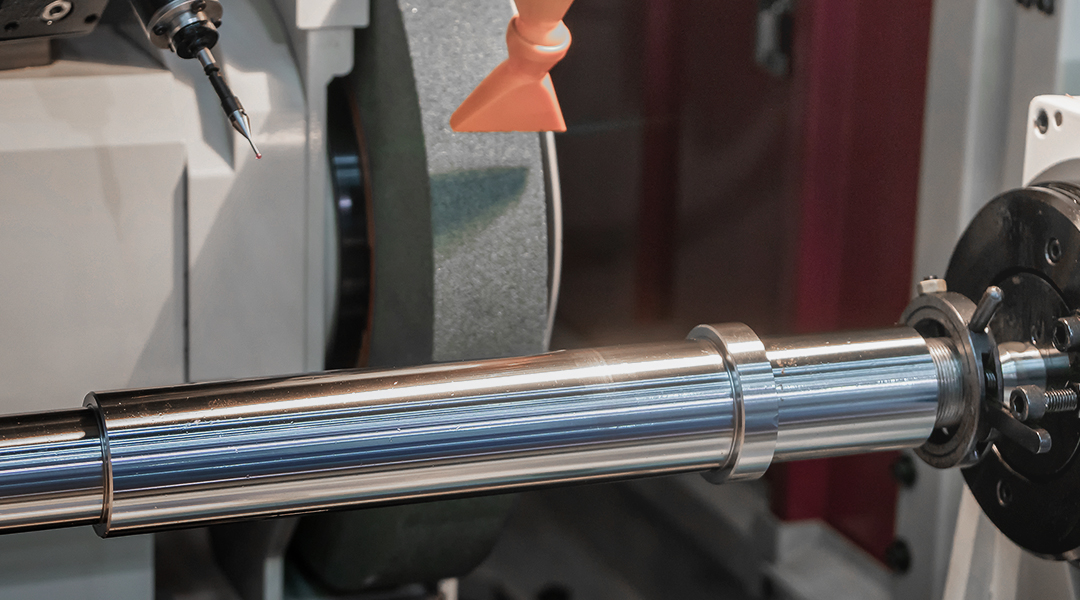

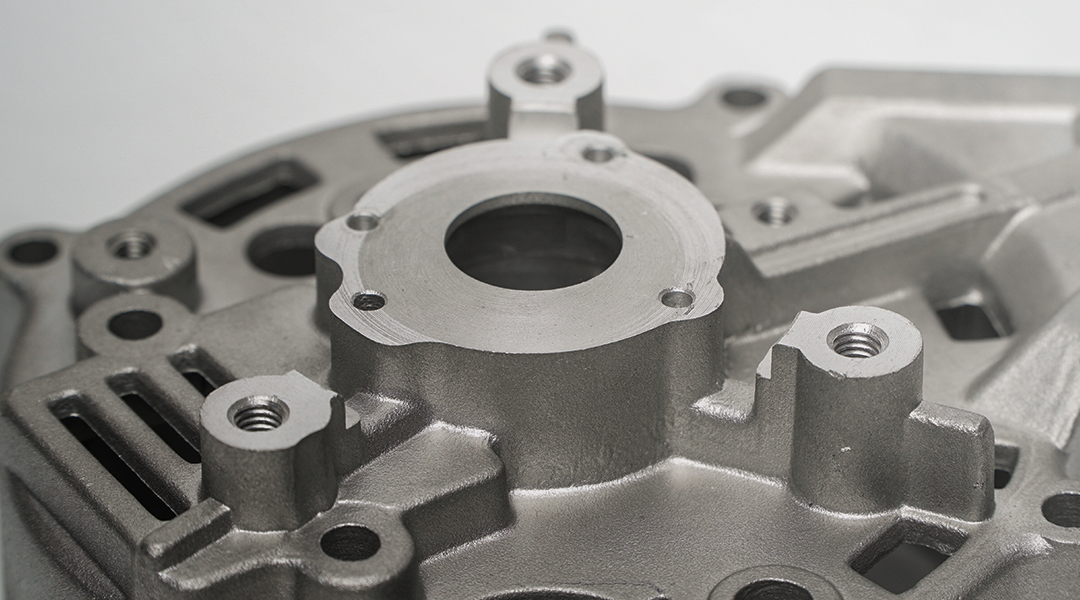

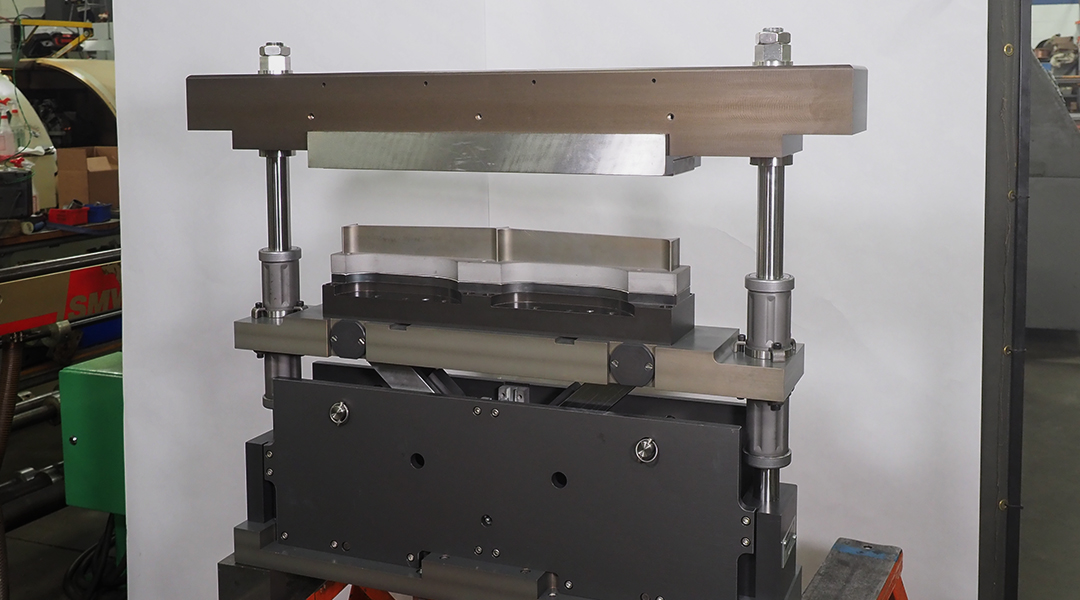

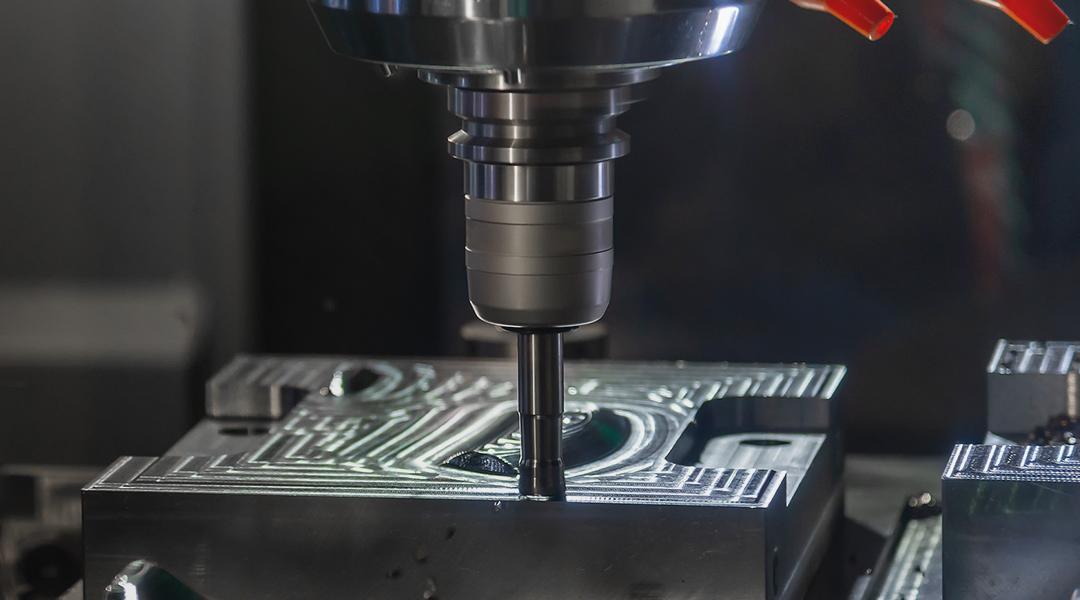

CNC Machining

CNC machining, at Mahuta Tool, is a versatile process that combines computer control with precision engineering. It allows us to create complex, custom metal components with utmost accuracy and consistency. From aerospace parts to medical devices, our CNC machining services cater to a wide range of industries, offering the perfect blend of technology and craftsmanship.