Wisconsin Multi-Axis Machining Service

Expertise in 3, 4 and 5-Axis CNC

Mahuta Tool provides multi-axis milling services specializing in prototyping and short-run production. Our multi-axis machining center provides 3, 4, and 5-axis milling to businesses in Wisconsin and throughout the Midwest, nationwide, and Canada.

Why Choose Mahuta Tool for Multi-Axis Machining?

Choose Mahuta Tool for your multi-axis machining needs and benefit from our expertise, state-of-the-art equipment, and commitment to quality. With extensive experience in multi-axis machining, we deliver precise and efficient solutions for complex projects. Our advanced CNC machining services ensure high-quality components with tight tolerances and intricate geometries. From 3-axis to 5-axis machining, we have the versatility to meet your requirements and exceed your expectations. Trust Mahuta Tool for reliable and tailored multi-axis machining solutions.

What is Multi-Axis CNC Machining?

- 3-Axis Machining: Utilizes three axes (X, Y, and Z) to machine planes or convex shapes, ideal for tasks like hole drilling, slot milling, and creating sharp edges.

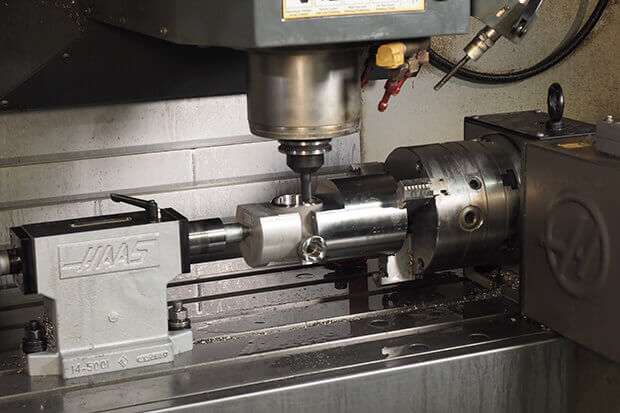

- 4-Axis Machining: Adds a fourth rotary axis to machine features on curved surfaces, offering enhanced efficiency and precision compared to conventional 3-axis milling equipment.

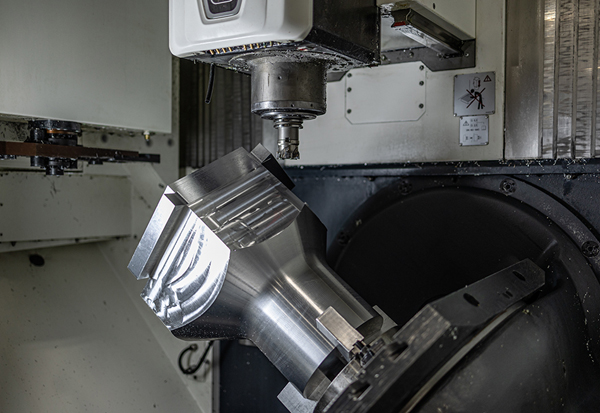

- 5-Axis Machining: Incorporates an additional rotational axis (B-axis) to achieve multidimensional tool movement, enabling the creation of complex parts with unparalleled precision and speed. 5-axis machining is important for high-level uses, such as aerospace and power generation applications.

Our CNC Machining Capabilities

At Mahuta Tool, we offer a comprehensive range of CNC machining capabilities to meet the diverse needs of our clients. Our state-of-the-art facility and experienced team enable us to deliver precision machining solutions for a wide range of applications.

Vertical CNC Machining

Using vertical 5-axis CNC milling technology, we have the capability to produce a variety of components and equipment with exceptional precision. From turbines and engine parts to fittings and spacers, our vertical machining center can handle complex geometries and tight tolerances. We work to close tolerances of +/-.0001”, ensuring the highest level of accuracy in every part we produce. Additionally, our ISO 9001:2015 certified quality management system and Mil-Spec compliance guarantee quality and reliability in every project.

Horizontal CNC Machining

Our horizontal CNC machining capabilities allow us to efficiently produce large components with complex geometries. Whether you need parts for aerospace, automotive, or medical applications, our horizontal machining center can handle the job with precision and accuracy.

Large & Short Run CNC Machining

Whether you need a single prototype or thousands of parts, we have the capabilities to handle both large and short production runs. Our efficient machining processes ensure fast turnaround times without sacrificing quality, making us your trusted partner for all your machining needs.

Prototype CNC Machining

We understand the importance of rapid prototyping in product development. That's why we offer prototype CNC machining services to help bring your ideas to life quickly and cost-effectively. Our experienced team can turn your concept into a tangible prototype, allowing you to test and iterate before full-scale production.

Common Industries We CNC Machine Parts

No matter the industry, Mahuta Tool is committed to delivering precision CNC machining solutions that meet the unique needs and requirements of our clients.

CNC Machining for the Aerospace Industry

Precision and reliability are crucial in aerospace. Our CNC machining expertise ensures that every aerospace component meets strict quality standards and tolerances, guaranteeing safety and performance. From aircraft components to satellite parts, every piece must meet strict quality standards and tolerances. We’re capable of creating intricate parts that meet the rigorous demands of the aerospace industry, ensuring safety and performance in every application.

CNC Machining for the Automotive Industry

From engine parts to transmission components, we provide CNC machining solutions for automotive applications. Our technology and experienced team deliver high-quality parts with tight tolerances for optimal performance. Whether it's prototyping or large-scale production, we have the capabilities to meet the needs of the automotive sector.

CNC Machining for the Medical Industry

We produce precise medical components, from surgical instruments to implantable devices. Our CNC machining capabilities meet stringent quality standards, ensuring safety and effectiveness in medical applications. With our advanced CNC machining capabilities, we help medical device manufacturers bring innovative products to market while maintaining the highest levels of quality and reliability

CNC Machining for the Defense Industry

At Mahuta Tool, our multi-axis CNC machining capabilities meet the stringent demands of military applications. We manufacture essential components such as aerospace couplers, aircraft seat frames, clamshells, helicopter components, and flanges with precision and reliability. Our expertise ensures that each part adheres to strict quality and performance standards, making us a trusted partner for high-quality, reliable CNC machined parts in the military industry.

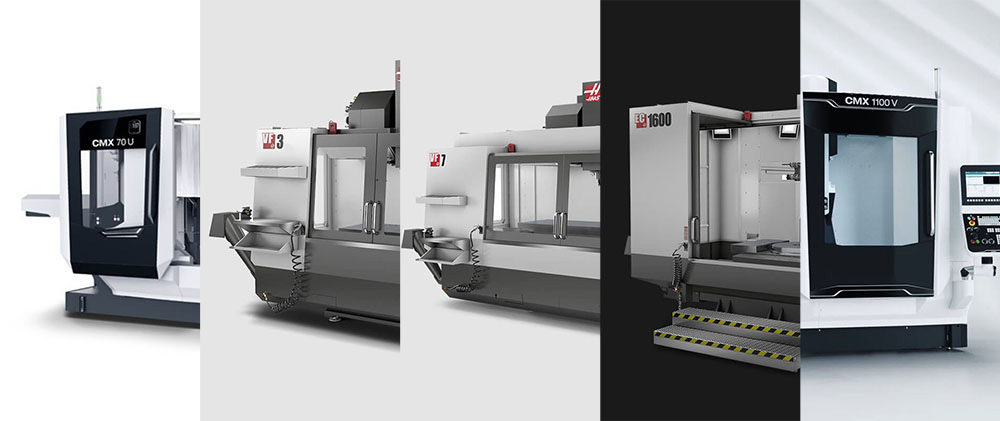

DMG Mori CMX 70 U 5-Axis

CMX U series realizes high productivity, flexibility and operatively with the modern C-frame design. Integrated NC-controlled B- and C-axis table and inherently stable, mineral cast composite bed deliver maximum stability. This applies to the modularity and possibility to build up “your own machine” with a wide range of hardware and software options, a variety of 3D controls and technological solutions.

29.5” X 23.5” X 20.5”

Vertical

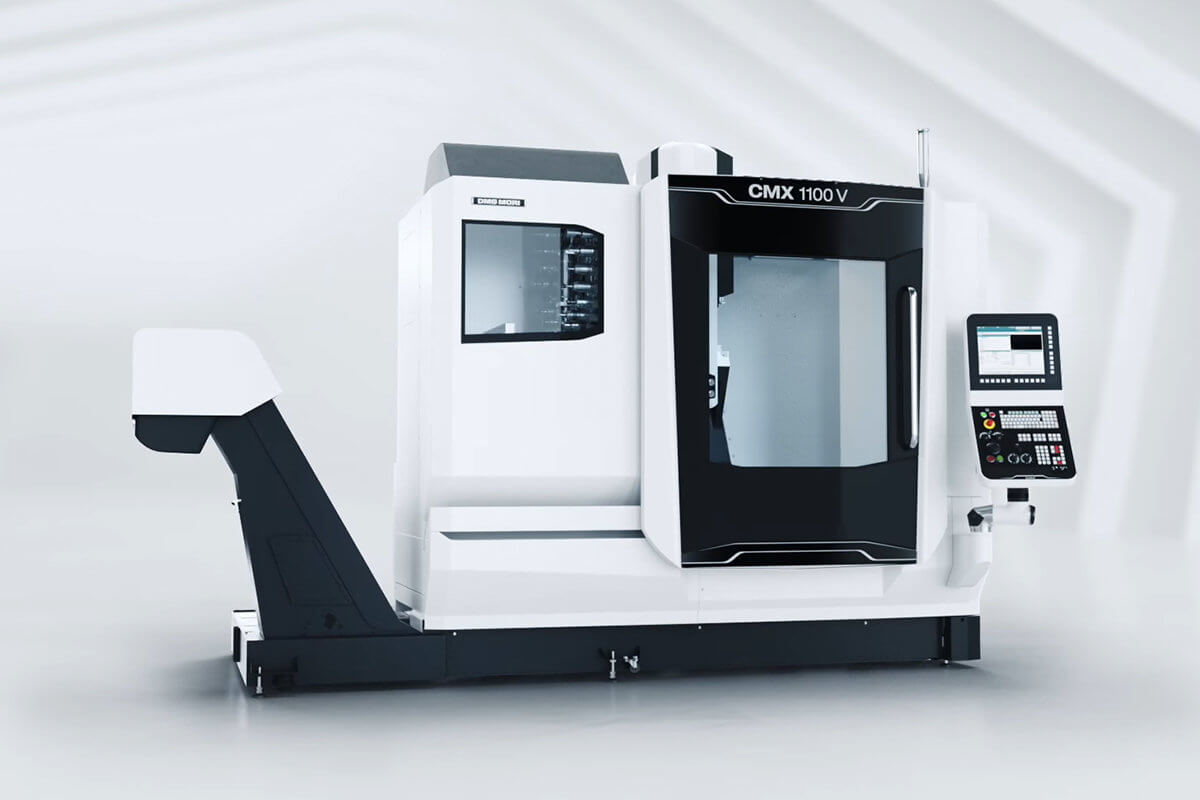

DMG Mori CMX 1100V 5 Axis

DMG Mori's CMX 1000V 5-axis provides precision in every component and detail. It’s capable of positioning accuracy down to 0.00023 inches on all axes. This machine's sophisticated design provides a small footprint and large working area, making it perfect for any manufacturing environment.

43/3" x 22" x 20.1"

Vertical

HAAS EC-1600 HMC

Thanks to a large work cube and a maximum part capacity of 10,000 lb., the Haas EC-1600 is the perfect solution for any large-part machining requirements. For this reason, the EC-1600 is one of the more popular 3-axis machines on the market.

62" x 40" x 32"

Full Axis Rotary

HAAS VF-7/41 with 4th Axis

As a member of Haas' industry-leading VF Series, this machine is one of the best-value, high-performance machine tools available. The VF-7 allows for machining of high-quality large parts.

84" x 32" x 30"

Vertical

HAAS VF-3 with 4th Axis

As a member of the Haas VF Series family, this machine is an industry leader in high-performance machine tools. The VF-3 features a larger work envelope than the VF-1 and VF-2, allowing for machining of medium-sized, high-quality parts.

40" x 20" x 25"

Vertical

Multi-Axis CNC Machining Services Across the United States

Mahuta Tool Corp. specializes in Multi-Axis CNC Machining services for clients in Wisconsin, Illinois, Michigan, Indiana, Minnesota, Iowa, Missouri, North Dakota, South Dakota, and Ohio. Our state-of-the-art facility is equipped for complex multi-axis machining projects. Contact us for precision engineering that meets your specifications.